e18 standard test methods for rockwell hardness of metallic materials|standard rockwell hardness scale : broker 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell indentation hardness prin-ciple. . Magrinha Slots is on Facebook. Join Facebook to connect with Magrinha Slots and others you may know. Facebook gives people the power to share and makes the world more open and connected.

{plog:ftitle_list}

web16 de mar. de 2021 · A endorfina é um neuro-hormônio, ou seja, uma substância natural, produzida pela glândula hipófise, presente no cérebro. Ela inibe a irritação e o estresse, contribuindo para a sensação de .

Standard Test Methods for Rockwell Hardness of Metallic Materials. Significance and Use. 4.1 The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials.1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell indentation hardness prin-ciple. . 1. Scope* tallic materials by the Rockwell indentation hardness prin-ciple. This standard provides the requirements for Rockwell hardness ma. ing the direct and indirect .

The revision of E 18 requires that all performance verifications of Rockwell hardness indenters and hardness machines must be made using test blocks calibrated traceable to the Rockwell . This document provides guidance for Rockwell hardness machines and the procedures for performing Rockwell hardness tests of metallic materials, detailing the necessary principles, procedures, .Standard Test Methods for Rockwell Hardness of Metallic Materials. 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell indentation .1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell indentation hardness principle. .

1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the verification of .

standard rockwell hardness scale

Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials E0018-02 ASTM|E0018-02|en-US Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials Standard E18 Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of .ASTM E18 – Standard Test Methods for Rockwell Hardness of Metallic Materials. Scope. ASTM E18 is a standard test method used to determine the Rockwell hardness of metallic materials. Rockwell hardness is a measure of a material’s resistance to indentation, similar to Brinell hardness. However, the Rockwell test uses a diamond indenter or a .1.4 Units — At the time the Rockwell hardness test was developed, the force levels were specified in units of kilograms-force (kgf) and the indenter ball diameters were specified in units of inches (in.). This standard specifies the .1.4 Units— At the time the Rockwell hardness test was developed, the force levels were specified in units of kilograms-force (kgf) and the indenter ball diameters were specified in units of inches (in.). This standard specifies the units of force and length in the International System of Units (SI); that is, force in Newtons (N) and length in millimeters (mm).

The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.

rockwell standard e18

Designation: E18 – 11 Standard Test Methods for Rockwell Hardness of Metallic Materials 1, 2 Arman Farhadpour This standard is issued under the fixed designation E18; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision.1.4 Units— At the time the Rockwell hardness test was developed, the force levels were specified in units of kilograms-force (kgf) and the indenter ball diameters were specified in units of inches (in.). This standard specifies the units of force and length in the International System of Units (SI); that is, force in Newtons (N) and length in millimeters (mm).

Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials E0018-00 ASTM|E0018-00|en-US Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials Standard E18 Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of .

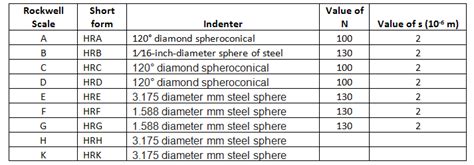

This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges and consequently the widest variety of materials and applications (see table below).Designation: E18 22 An American National Standard Standard Test Methods for Rockwell Hardness of Metallic Materials 1,2 This standard is issued under the Þxed designation E18; the number immediately following the designation indicates the year of original . ness of Metallic Materials E110 Test Method for Rockwell and Brinell Hardness of

The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.Designation: E18 − 20 An American National Standard Standard Test Methods for Rockwell Hardness of Metallic Materials1,2 This standard is issued under the fixed designation E18; the number immediately following the designation indicates the year of original . ISO 6508-1 Metallic Materials—Rockwell Hardness Test— . 4.1 The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.

torsion field testing

Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell indentation hardness principle.ASTM-E18 Standard Test Methods for Rockwell Hardness of Metallic Materials - hardness; mechanical test; metals; Rockwell; . The new 2012 revision replaces the previous ASTM E18-11 Edition, which is now obsolete. Three sections have .

These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell indentation hardness principle. This standard provides the requirements for Rockwell hardness machines and the procedures for performing Rockwell hardness tests.Designation: E18 −14E18 14a An American National Standard Standard Test Methods for Rockwell Hardness of Metallic Materials1,2 This standard is issued under the fixed designation E18; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision.1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the verification of machines for Rockwell hardness testing (Part B) and the calibration of standardized hardness test blocks (Part C).

4.1 The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials. Standard Test Methods for Rockwell Hardness of Metallic Materials active Buy Now. Details. History. . ASTM E18-22 May 1, 2022 . 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the verification of machines for. ASTM E18-05.Designation: E18 − 19 An American National Standard Standard Test Methods for Rockwell Hardness of Metallic Materials1,2 This standard is issued under the fixed designation E18; the number immediately following the designation indicates the year of original . ISO 6508-1 Metallic Materials—Rockwell Hardness Test— .These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the verification of machines for Rockwell hardness testing and the calibration of .

torsion impact test

Revision of E18-22 Standard Test Methods for Rockwell Hardness of Metallic Materials Rationale Section 5.5.3 has a mandatory provision that small diameter cylindrical specimen be supported using a v-anvil and thus have hardness tested on a convex surface.ASTM-E18 Standard Test Methods for Rockwell Hardness of Metallic Materials - hardness; mechanical test; metals; Rockwell; . The new 2012 revision replaces the previous ASTM E18-11 Edition, which is now obsolete. Three sections have .5.1.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. The significant difference between the two test classifications is in the test forces that are used. For the Rockwell hardness test, the preliminary test force is 10 kgf (98 Standard Test Methods for Rockwell Hardness of Metallic Materials inactive Buy Now. Details. History. . ASTM E18-20 . 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the verification of machines for. ASTM E18-05.

The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.

rockwell hardness testing standard

Resultado da Jen’s Film Cameras 📸 ’s shop. 📸 Film, movie & digital cameras 💬 Worldwide Shipping! All Selling Sold Likes. Something went wrong.

e18 standard test methods for rockwell hardness of metallic materials|standard rockwell hardness scale